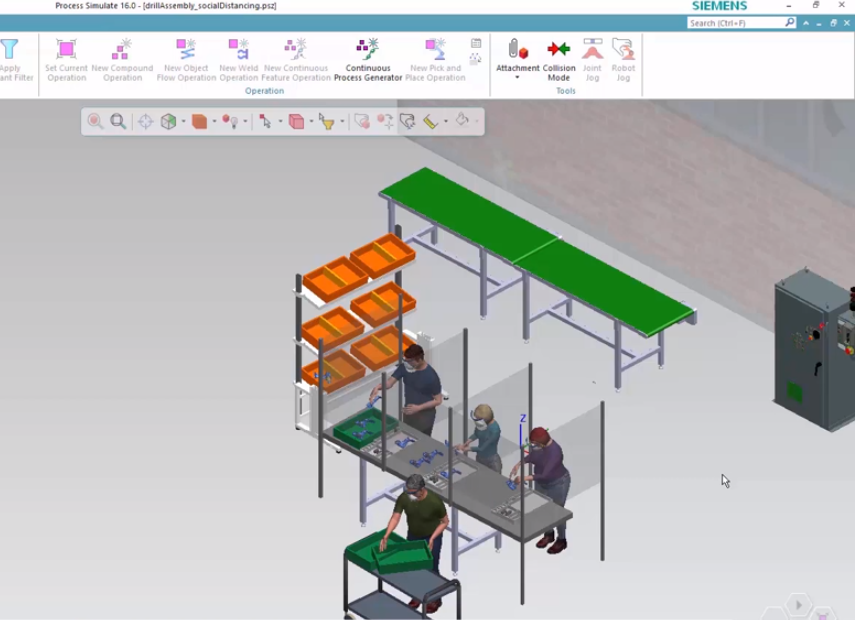

Model, simulate and optimize a comprehensive digital twin of your manufacturing processes—including robots, automation, material handling systems and people—to improve the performance of your business..

Use simulation and optimization for automated or manual production processes to evaluate and implement advanced manufacturing techniques, equipment and operations for more flexible manufacturing.

Use a realistic and immersive, high-fidelity environment with physics-based modeling, simulation and optimization tools to speed your innovation.

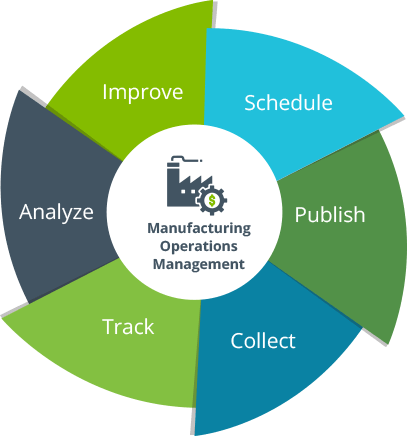

Tecnomatix is a comprehensive portfolio of digital manufacturing solutions that help you to digitalize manufacturing and the process of turning innovative ideas and raw materials into transformative products. With Tecnomatix software and digital manufacturing, you achieve synchronization between product engineering, manufacturing engineering, production execution, and service engineering to maximize your manufacturing efficiency.

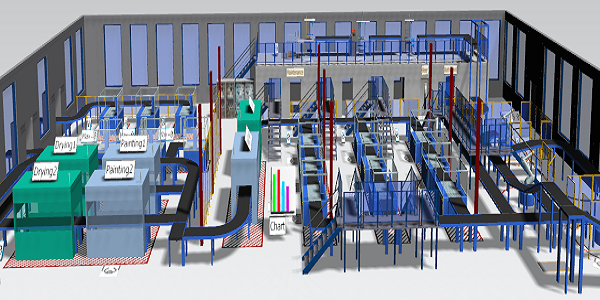

Quickly design, visualize, simulate and optimize complete production layouts with less risk and at lower cost, and easily associate them to manufacturing plans using a single system

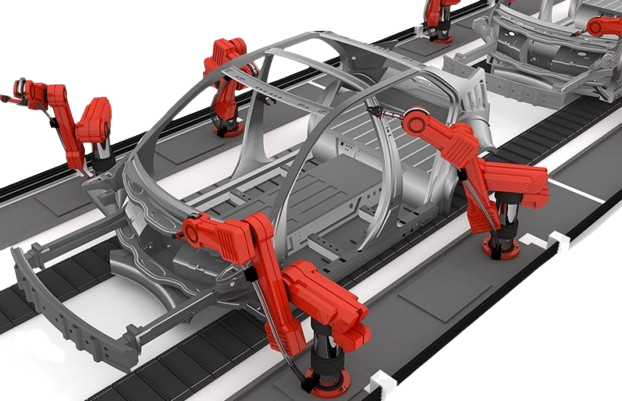

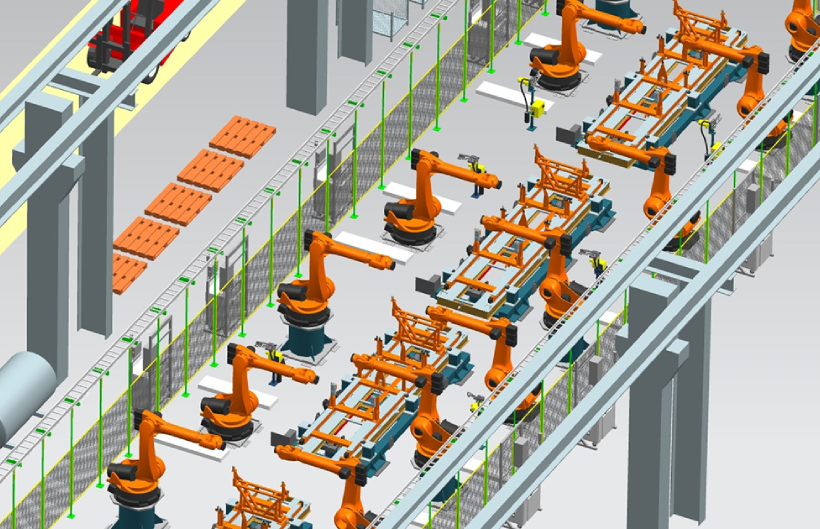

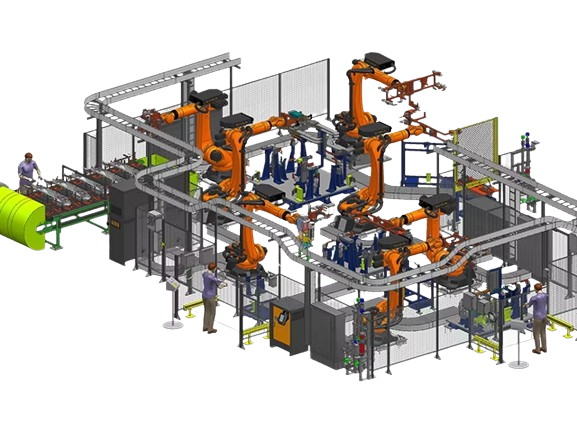

Engineer advanced robotic and automated production systems and optimize their performance using 3D robotic work-cell design, offline robotics programming, robotics simulation and virtual commissioning software.

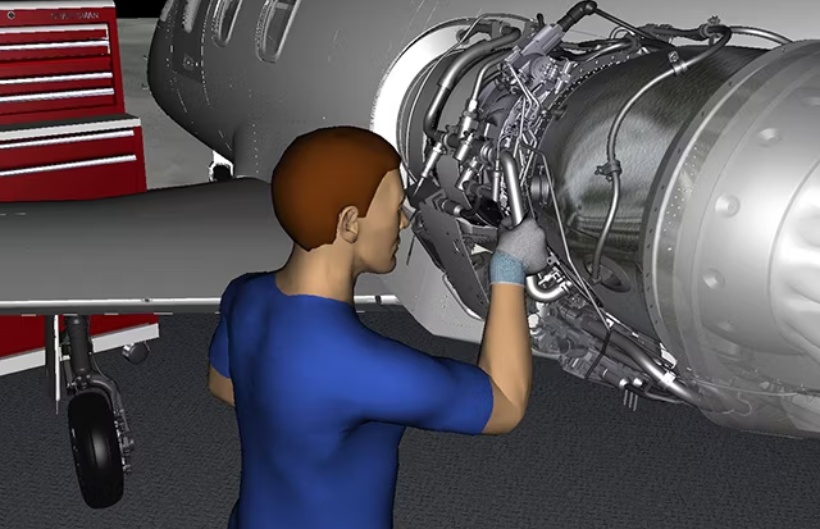

Design products with improved ergonomics in mind and assess human factors for operations to help plan safer workplaces

Create and manage the manufacturing bill of materials (MBOM) and the bill of process (BOP) to capture “what to make” and “how to make it,” generate work instructions for the shop floor, perform detailed operation time analysis, balance production lines and much more, while providing close collaboration between engineering, manufacturing and execution teams..

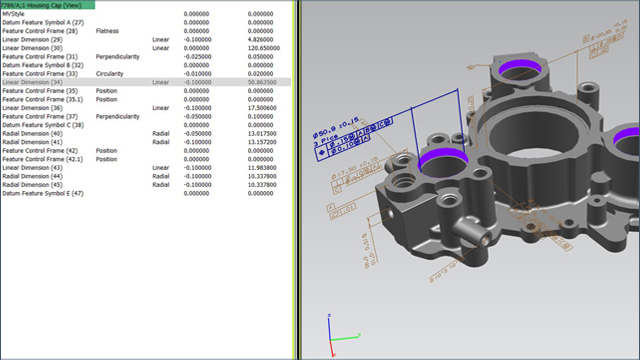

Integrate quality parameters during product design, manufacturing planning and production to ensure dimensional and build quality, and to help eliminate costly manufacturing quality issues on the factory floor.

Design assembly lines, equipment and tool requirements in a 3D environment. Optimize factory space and maximize capital resource utilization by digitally configuring factory layouts.

Plan, simulate and validate human tasks, robotics processes and automation during the entire product development lifecycle from concept, engineering and commissioning to production and continuous improvement.Leverage 3D models of products and resources to facilitate simulation, validation, optimization and commissioning of complex manufacturing processes involving equipment and people for faster launches and higher production quality

Organizations adopting this software gain a competitive edge by combining traditional ergonomics and human factors assessment methods with cutting-edge visualization and simulation technologies..

Create well-structured, 3D hierarchical models of production facilities, lines and operations for fast and efficient modeling of discrete and continuous manufacturing processes using powerful object-oriented architecture and modeling capabilities.

Build and visualize in 3D using included libraries or external CAD data. Leverage the JT data format for 3D modeling & Siemens direct model technology for efficient loading and realistic visualization of large 3D simulation models without compromising simulation and analysis needs.

Advantage of built-in tools and graphical outputs to assess production system performance, including automatic bottleneck detection; throughput analysis; machine resource and buffer utilization; energy consumption; cost analysis; Sankey diagrams and Gantt charts