What is NX CAM?

NX CAM is an advanced computer-aided manufacturing (CAM) solution built on the Siemens NX platform. It provides end-to-end capabilities for 2.5-axis to 5-axis milling, turning, multi-function machining, and postprocessing—all within a unified environment. NX CAM enables seamless collaboration between engineering and manufacturing teams, streamlines toolpath generation, and reduces programming time.

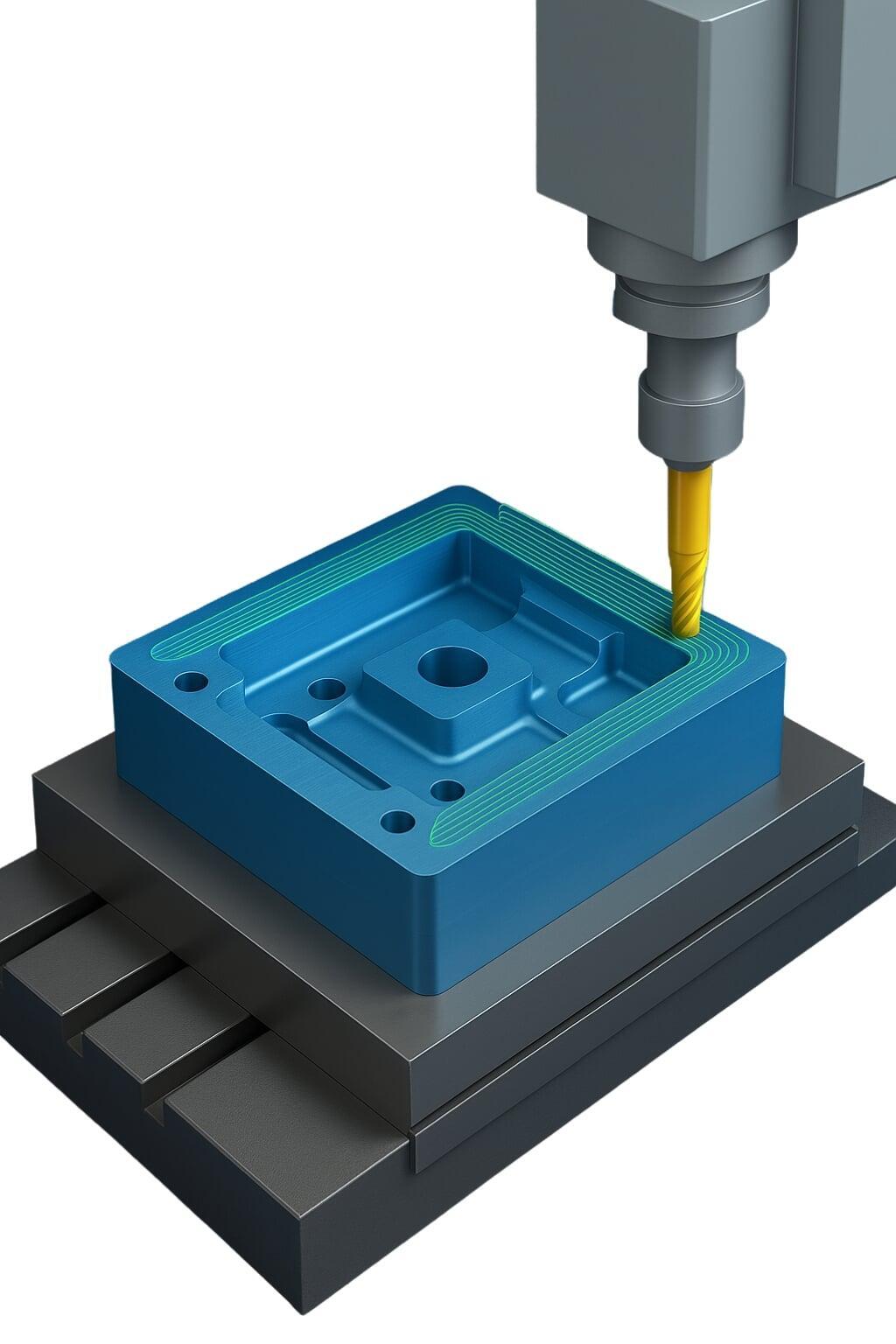

Prismatic parts machining

Quickly program prismatic parts using automated programming capabilities to create optimized milling and turning operations.

Mold, die and electrode machining

Manufacture micron-level precision tooling with integrated CAD/CAM software, using industry-leading design and machining capabilities.

Complex parts machining

Effectively machine the most challenging components using advanced multi-axis operations, using fewer setups and increasing part accuracy.

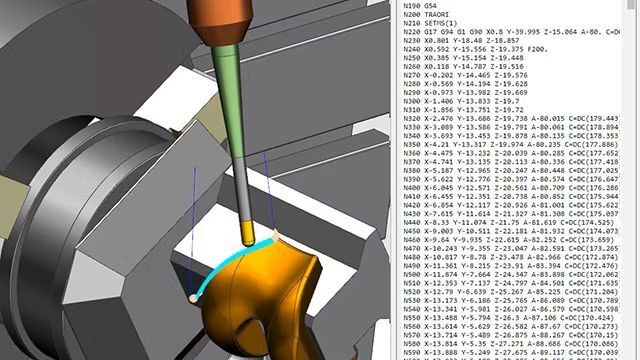

Postprocessing

Generate production-ready NC programs using cloud-based postprocessing solution with over 1,000 postprocessors and machine digital twins.

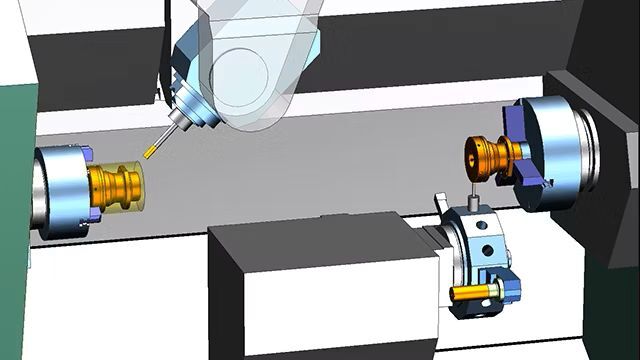

Machining simulation

Accurately validate machine tool motions using the integrated G-code-driven simulation, eliminating errors and maximizing machine uptime using few setups, while increasing part accuracy.

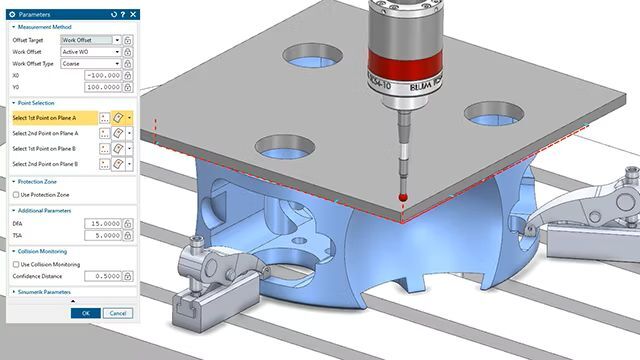

On-Machine Probing

Optimize machining accuracy with on-machine probing. Inspect parts, minimize setup time, rework and ensure precision with adaptive control detecting tool wear and adjusting for breakage.