Optimize Complex Mechatronic Systems

Simcenter Amesim

In today’s fast-paced and competitive industries, the ability to predict and optimize system behavior before physical prototypes are built is a game-changer. Simcenter Amesim, part of the Siemens Simcenter portfolio, enables model-based design of complex multi-domain systems. Whether you're working on automotive, aerospace, industrial machinery, or energy systems, Simcenter Amesim helps you reduce design cycles, cut costs, and boost innovation—right from the start.

What is Simcenter Amesim?

Simcenter Amesim is a leading 1D system simulation platform used to model, analyze, and optimize the behavior of multi-domain systems. It combines ready-to-use libraries with robust simulation capabilities, helping engineers evaluate the dynamic performance of systems involving mechanical, hydraulic, pneumatic, thermal, electrical, and control components—all in one platform.

Simcenter Amesim Software Features

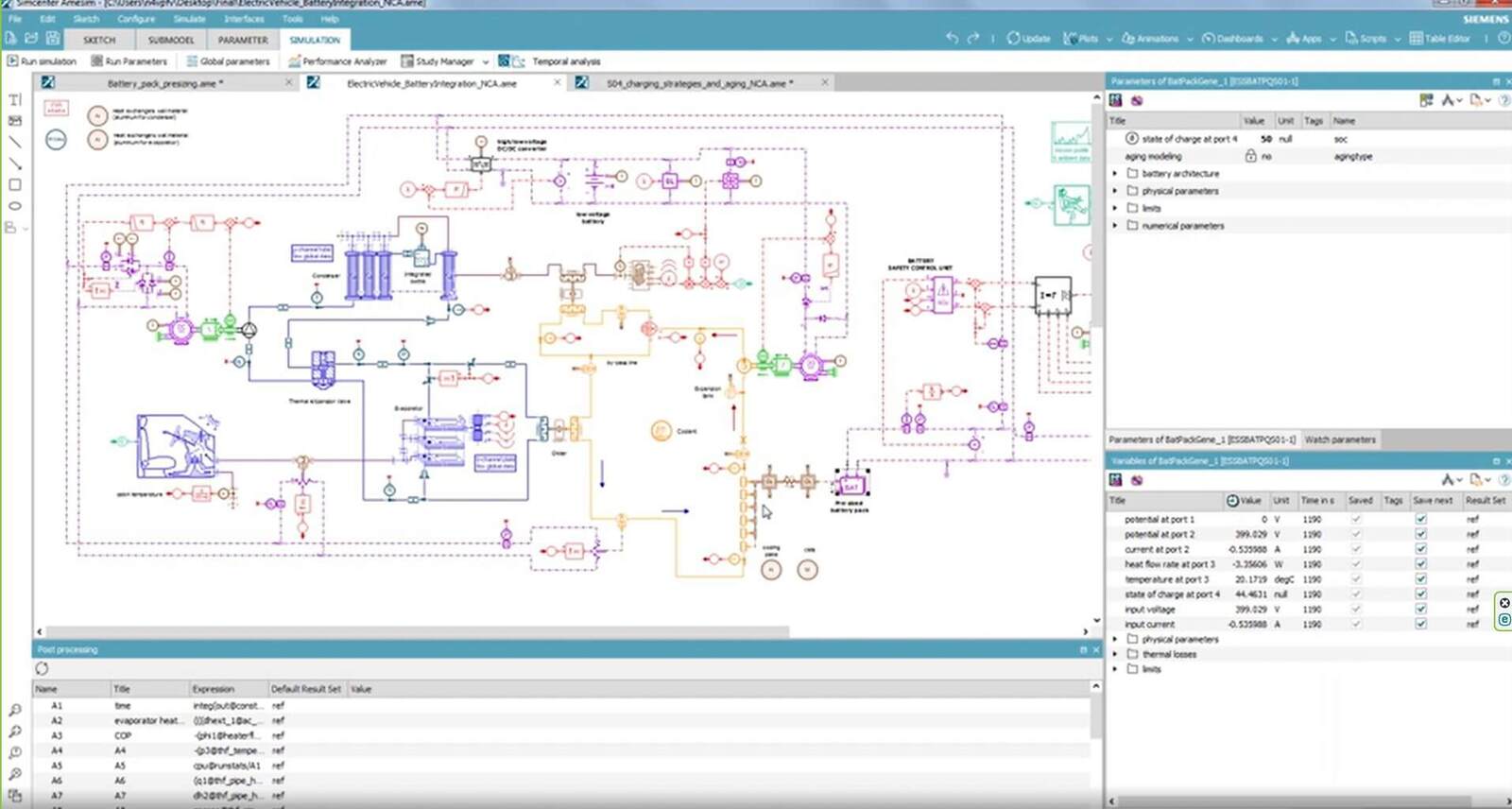

Optimize the dynamic behavior of hydraulic and pneumatic components while limiting physical prototyping to what's strictly necessary. With a wide choice of components, features and application-oriented tools, Simcenter Systems allows you to model fluid systems for a wide range of applications, such as mobile hydraulic actuation systems, powertrain systems or aircraft fuel and environmental control systems.

Comprehensive component libraries support occasional and expert users when modeling fluid systems, from functional to detailed models. The seamless integration between libraries enables the design of any fluid system and the coupling with controls and other related systems in a single platform.

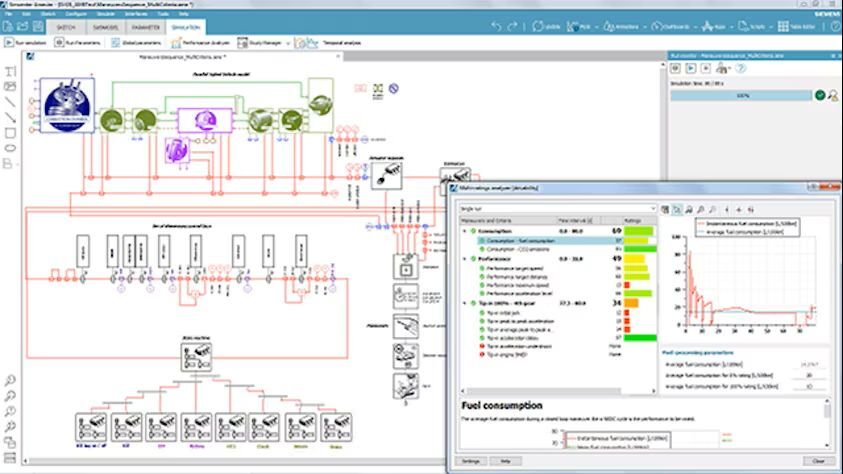

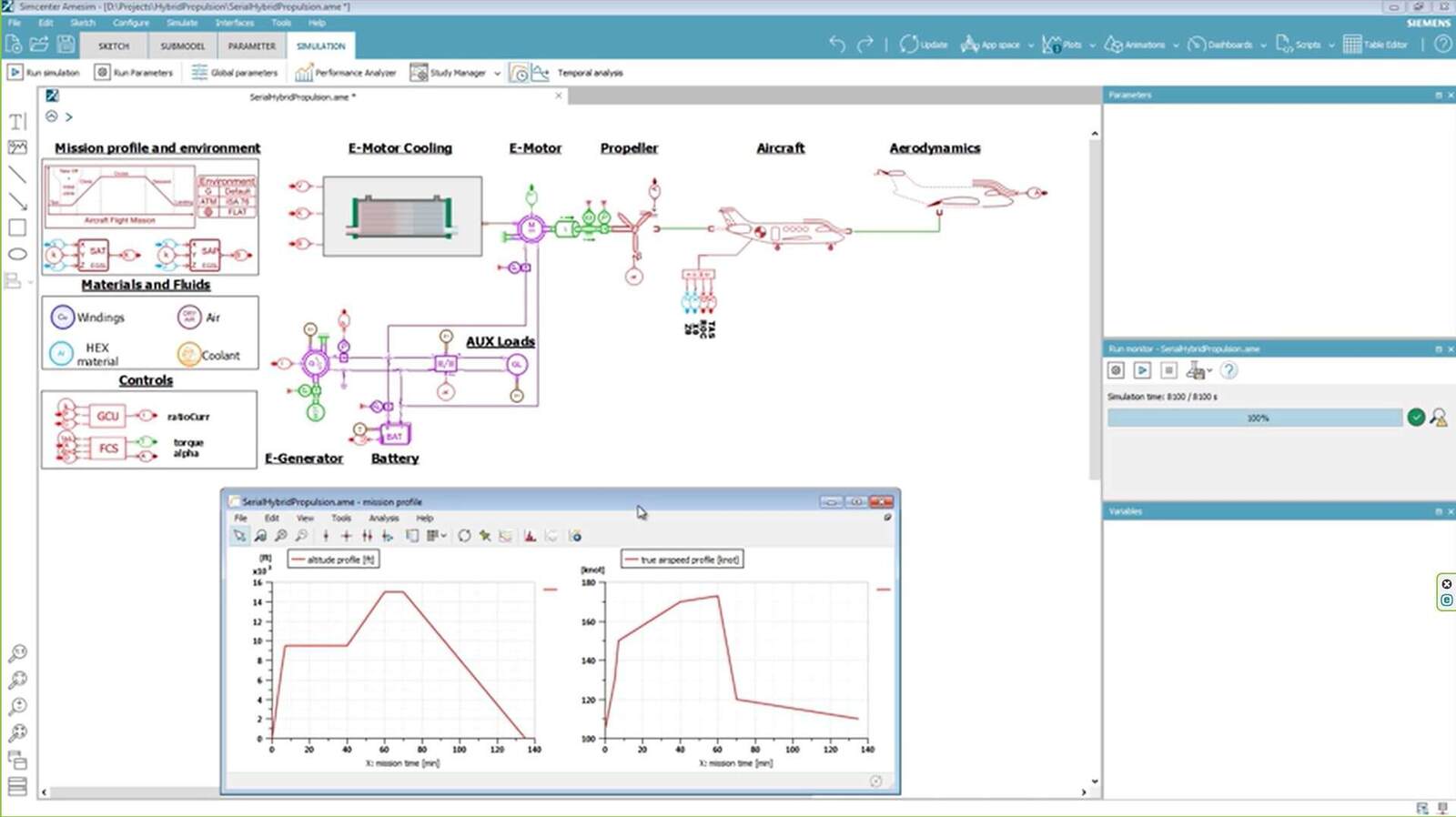

Address various architectures and technologies with the multiphysics system simulation approach. Powertrain electrification in automotive, reusable launch systems for the space industry, or the use of alternative fuels (LNG) for ships are examples of technology implementation that the modeling capabilities of Simcenter can support.

You will be able to design and assess the impact of the propulsion system on various metrics, such as onboard power generation or vehicle pollutant emissions, by performing a complete analysis of cross-system influences in a single platform.

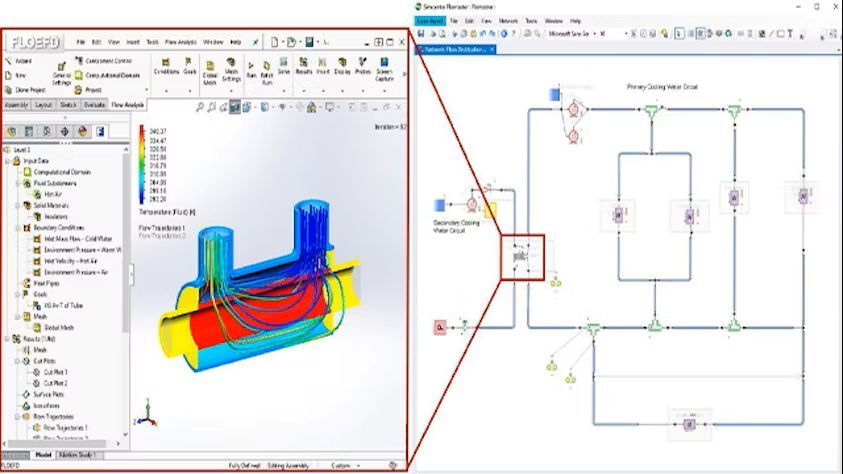

Simcenter Systems offers the integration of different simulation tools throughout the lifecycle of your system, from early design to the operation phase. This allows you to address the digital continuity challenge and increase the efficiency of your workflows and the collaboration between different departments.

Simcenter Systems supports connections to a product lifecycle management (PLM) system and geometrical data, co-simulations between 1D and 3D CAE tools, design space exploration, model-based controls development and interactions among different systems using the functional mockup interface (FMI).

Simcenter Systems helps maximize thermal performance for HVAC and cabin comfort, vehicle thermal management, environmental control systems or other thermal systems. Advanced post-processing features that graphically visualize energy flows in your system make it highly effective to optimize energy efficiency and to study the integration of energy recovery systems and their impact on performance and energy consumption.

You can use the software to represent the real operating environment of your system, including interactions with surroundings when designing and validating your temperature control strategies.

Simcenter supports the creation of reduced-order models (ROM) in an intuitive interface, providing the best reduction techniques from machine learning, linear algebra and statistics.

A ROM has a small memory footprint, is tool-agnostic and can be operated in real-time, allowing for usage as an executable digital twin in all phases of the product lifecycle – enabling better decisions and improved operational excellence.

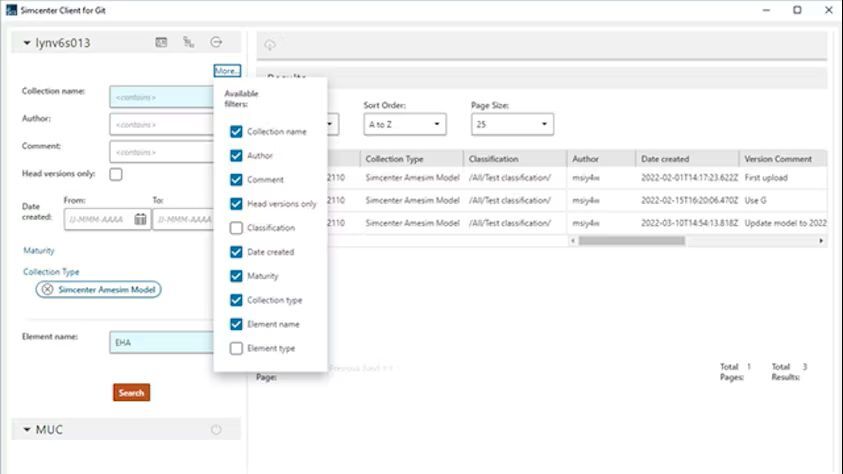

The Simcenter system simulation client for git option helps all the actors of the system simulation community to work collaboratively, supplying the daily management of simulation assets, including branching, versioning and role-based access control.

Using the client for git also allows you to keep track of dependencies, related content and all other data that is part of the model, so you have a precise representation of the system simulation domain.

Deploy collaborative model development most efficiently with the help of optimized data transfers and search algorithms combined with an efficient and fully integrated user experience.

Discover Simcenter Amesim

Explore how system simulation boosts product performance and cuts development time.

Key Capabilities

Multi-Domain System Modeling

Control System Integration

Real-World Applications

Validate performance of automotive powertrains, electric and hybrid vehicle architectures, aircraft systems, HVAC units, heavy equipment, and more—before physical testing begins.

Scenario & Parameter Analysis

Early Performance Prediction

How ProductSpace Can Help

Deep simulation expertise across industries

Certified Siemens solution partner

Proven success in deploying and scaling model-based engineering

Dedicated support and continuous improvement services

Not sure where to start? Our experts are here to help!

Succeeding Together

Our Services & Key Benefits

Technical Support

Ensure smooth operations with expert troubleshooting and system optimization. Our team provides fast, reliable support for PLM and CAD environments, ensuring minimal downtime.

Consultation & Training

Maximize efficiency with expert-led guidance tailored to your business needs. From system implementations to best practices, our consultants help you get the most out of your solutions.

Resource Library

Stay ahead with our collection of webinars, guides, Quick Bytes, and more. Explore expert insights, industry best practices, and practical solutions to optimize your PLM, CAD, and enterprise systems for success.