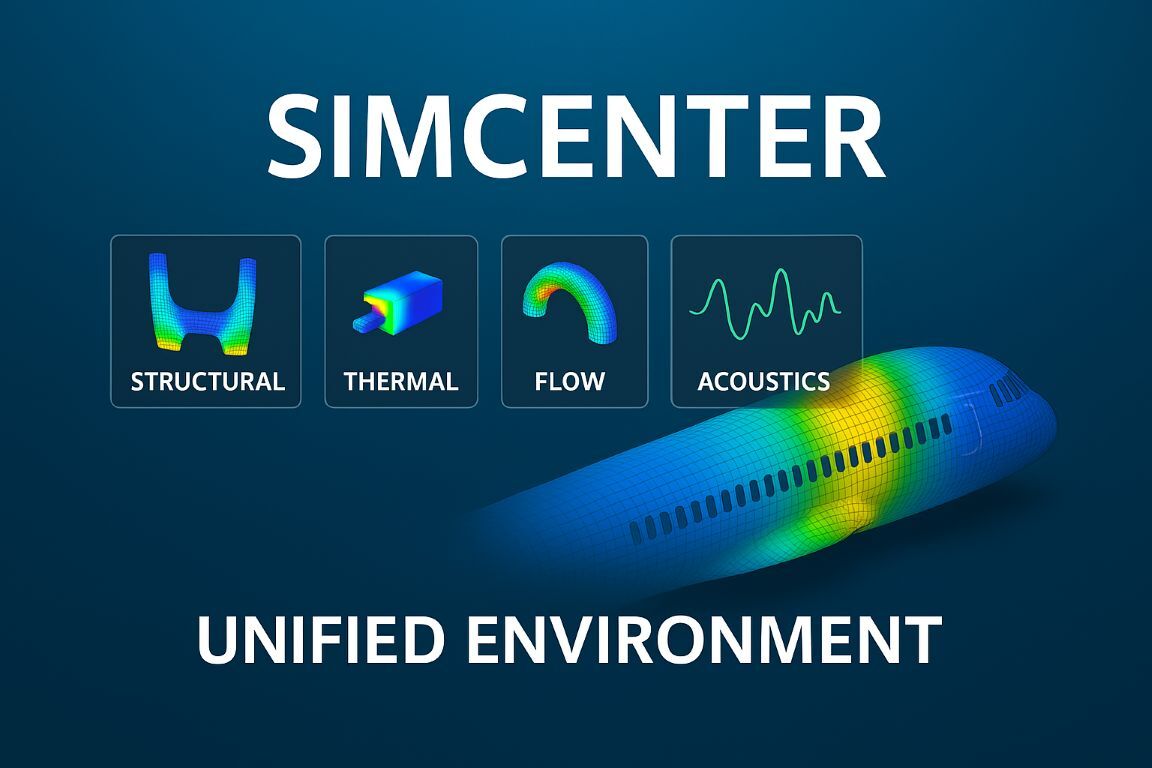

Predict, Validate, and Optimize Product Performance in One Powerful Platform

Simcenter 3D

In a fast-paced engineering world, simulation isn’t just a tool—it’s a competitive advantage. Simcenter 3D, part of Siemens’ Simcenter portfolio, delivers a powerful, integrated environment for advanced CAE simulation that empowers engineers to predict real-world performance across multiple physical domains.

What Is Simcenter 3D?

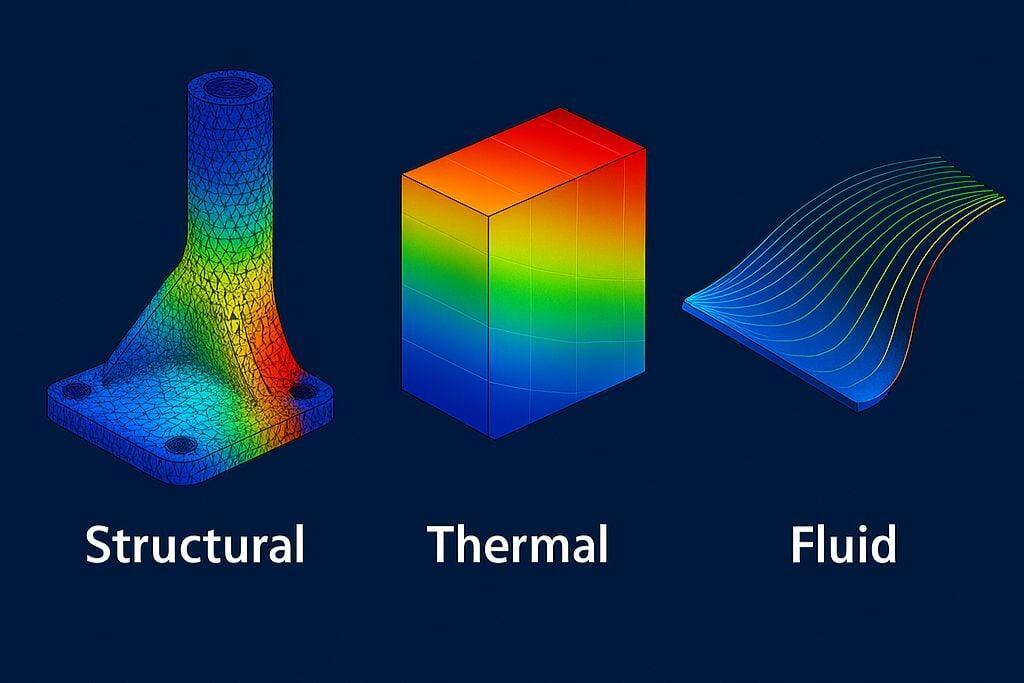

Simcenter 3D is a next-generation simulation platform that unifies structural, thermal, motion, flow, durability, and acoustic analyses within a single environment. It’s tightly integrated with NX CAD and Teamcenter PLM, enabling a seamless workflow from design through simulation to decision-making—without the need for data translation or platform switching.

Simcenter 3D software capabilities

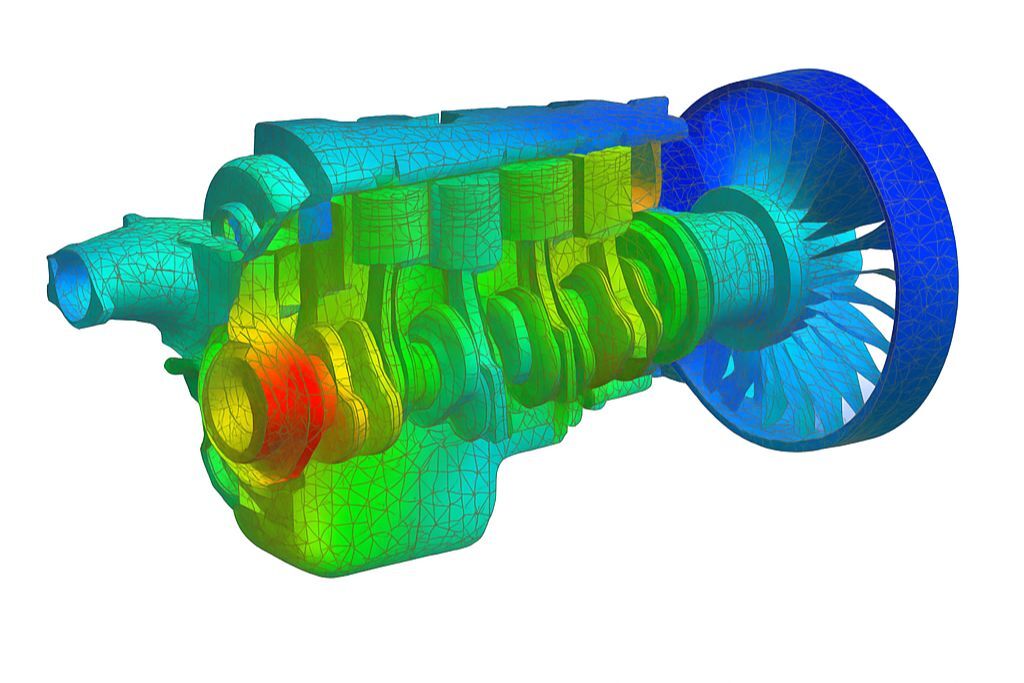

This integrated environment helps you to achieve faster CAE processes and streamline multidiscipline simulations that integrate any of the Simcenter 3D solutions together, like thermal-mechanical, vibro-acoustic or other more complex analyses. Simcenter 3D’s pre/post helps you to:

- Quickly and intuitively edit, defeature and abstract geometry

- Build any kind of mesh with comprehensive meshing tools

- Efficiently create and manage finite element (FE) assemblies

- Create, run and evaluate simulation models for multiple common third-party CAE solvers

- Efficiently launch and monitor simulations remotely

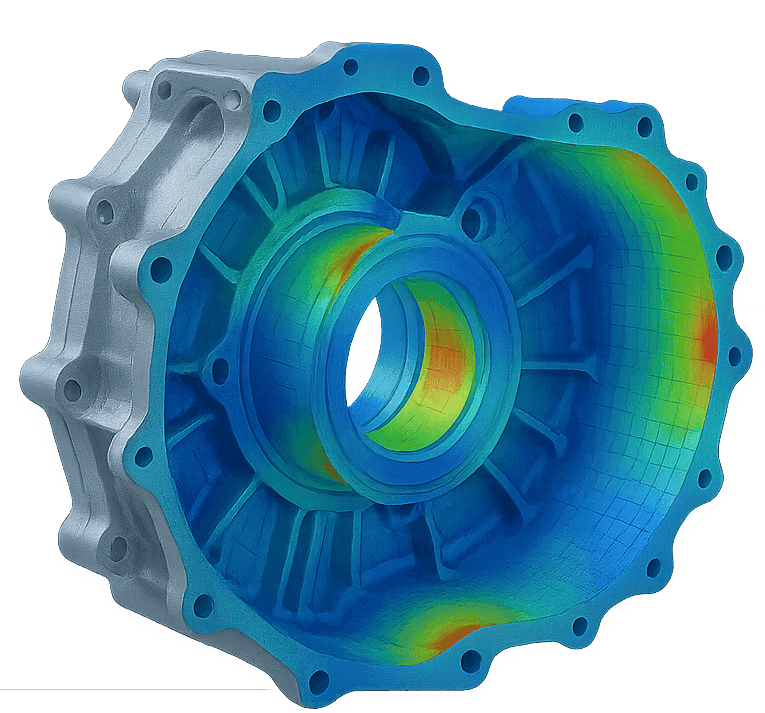

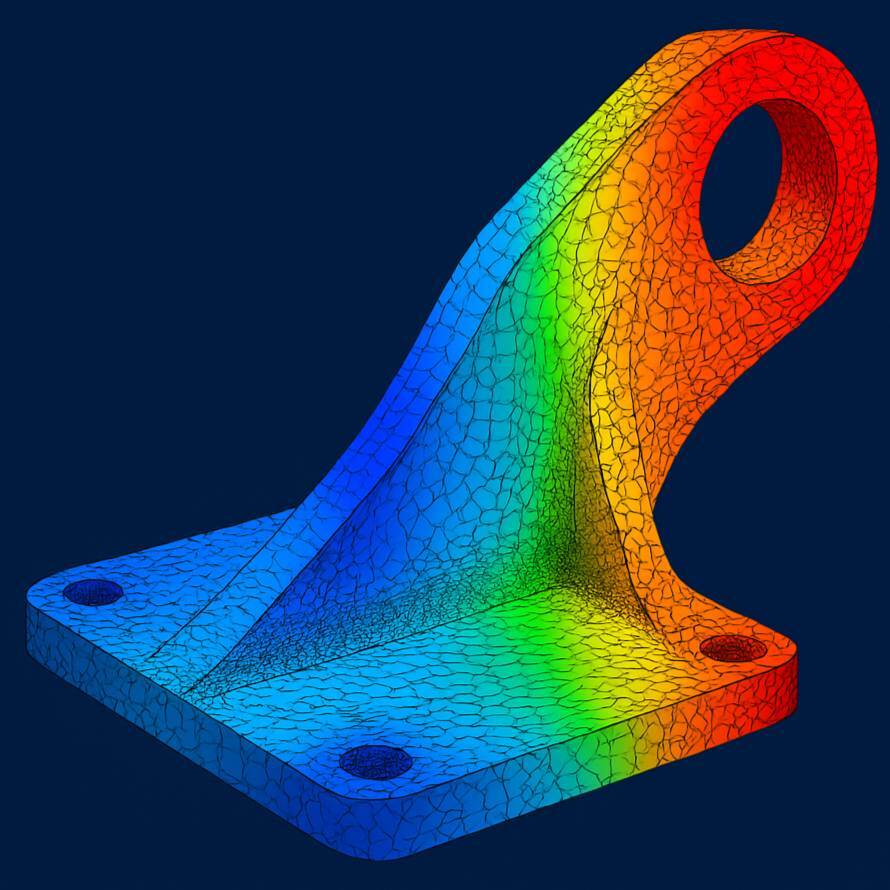

Simulate structures to understand how they perform for stress, deformation and more. Structural analysis solutions within Simcenter 3D are powered by the well-known Simcenter Nastran solver and can help you accurately simulate the following types of solutions:

- Linear analysis

- Multistep nonlinear analysis

Understand, analyze and improve structural dynamics response. Simcenter 3D structural dynamics solutions help you to efficiently understand and avoid excessive vibrations and stresses. Dedicated capabilities available within the structural dynamics solution include:

- Structural dynamics

- Noise, vibration and harshness (NVH)

- Rotor dynamics

- Response dynamics

Minimize noise and optimize sound quality through acoustic simulation. Simcenter 3D includes dedicated acoustic modeling capabilities, efficient solvers and easy-to-interpret visualization and auralization tools that allow you to quickly gain insight into a design’s acoustic performance for uncoupled acoustics, coupled vibro-acoustics and aero-acoustic applications. Specific acoustics capabilities include:

- Finite Element Modeling (FEM) and Boundary Elements (BEM) solutions

- Aeroacoustics and aero-vibro-acoustics

- Ray acoustics

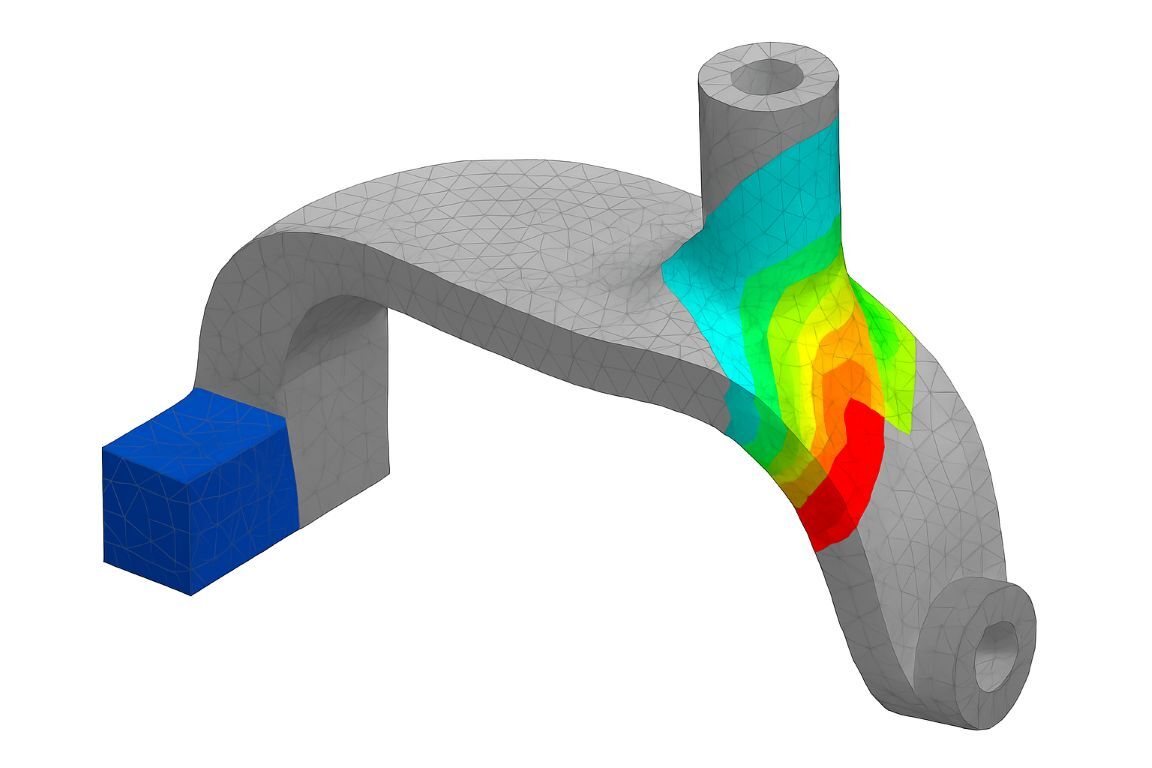

Perform in-depth fatigue and lifing analysis through an integrated suite of tools to support fatigue design in all stages of development. This includes easy-to-use wizards for strength and fatigue in the design phase; fatigue information on the current simulated part; detailed analysis of complex load scenarios, including weldments and connections; and new materials and manufacturing processes. Specific capabilities for durability include:

- Fatigue strength analysis

- Weld fatigue

- Composite fatigue

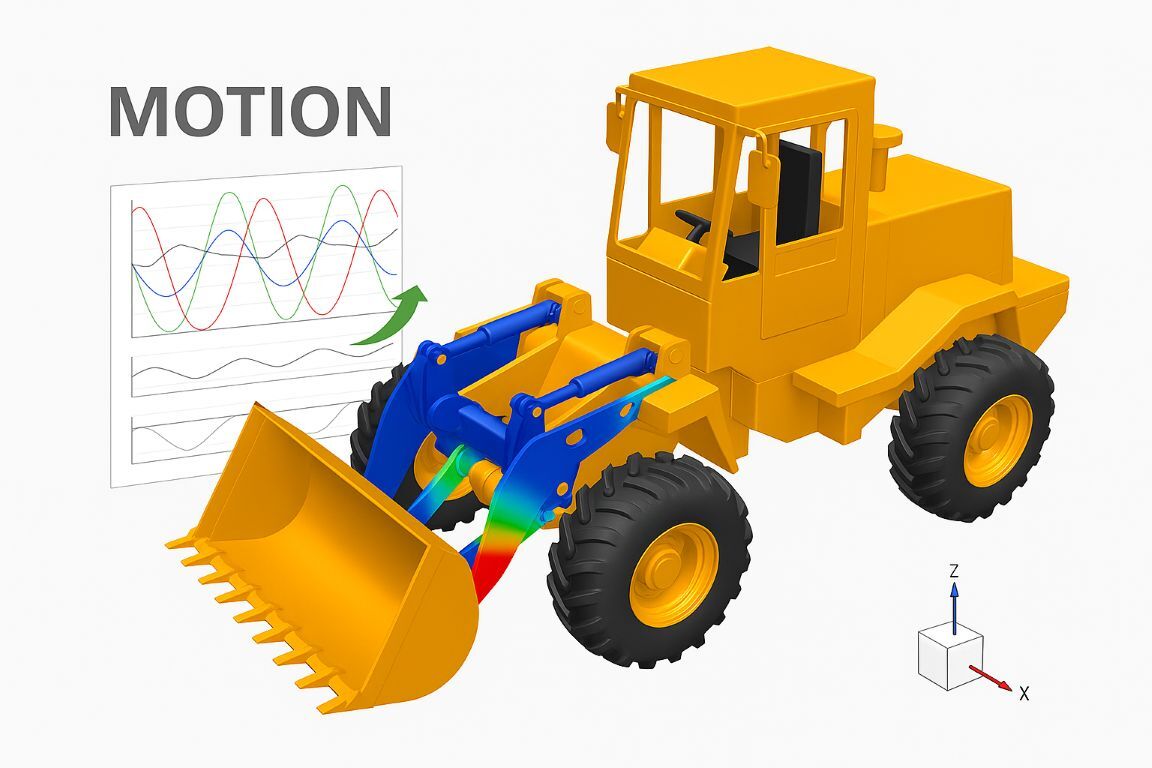

Simulate multibody dynamics to engineer performance for moving mechanisms. Simcenter 3D includes a complete and robust set of capabilities to support all aspects of advanced dynamic, static and kinematics motion simulation. The early use of motion simulation is key to evaluating mechanism performance to increase design confidence and reduce risks. Specific capabilities include:

- Rigid body and flexible body dynamics

- Control system integration

- Drivetrain, transmission and gears

- Interference checking

- Hardware-in-the-loop (HIL)

- Time waveform replication

- Driving dynamics

- Tire model integration

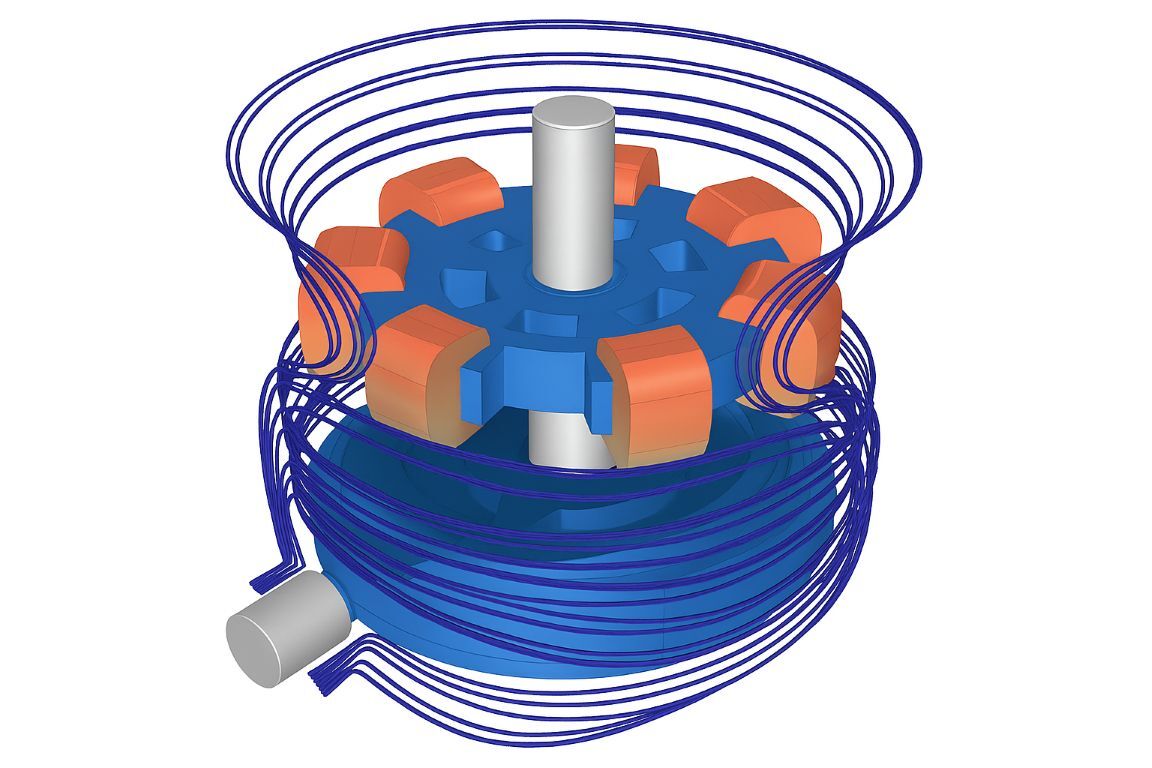

Integrate low-frequency electromagnetic solutions to achieve excellent performance. Simcenter 3D includes a comprehensive set of capabilities that provide insight into diverse design challenges, such as the performance of electromechanical components and energy conversion.

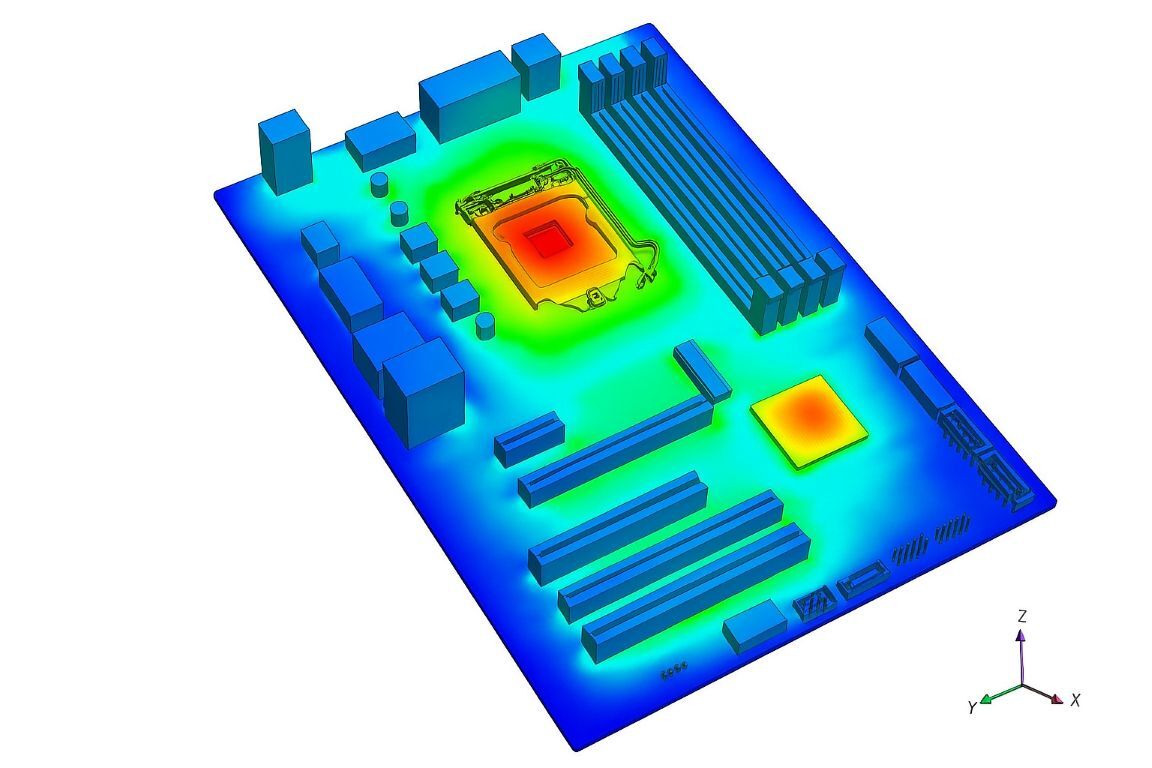

Simcenter 3D is a complete solution for modeling nonlinear and transient heat transfer phenomena. Dedicated thermal modeling capabilities help you rapidly create thermal connections, select the right physical model and define the right loads and boundary conditions. Simcenter 3D thermal analysis solutions include these specific capabilities:

- Conduction heat transfer

- Convection heat transfer

- Radiation heat transfer

- Conjugate heat transfer

- Space-systems thermal

Integrate domain solutions to solve real-world problems. Simcenter 3D streamlines multiphysics simulation through a common engineering desktop that is used for pre- and post-processing of multiple disciplines. Through this integrated platform, you can more easily perform multiphysics simulations such as thermal-fluid, thermo-mechanical, fluid-structure interaction, vibroacoustics, aero-vibro-acoustics, electromagnetic-thermal and electromagnetic-vibro-acoustic. Simcenter 3D also supports both weak and strong coupling depending on the physics types involved. Simcenter 3D performs multiphysics simulations using these different methods:

- One-way data exchange

- Two-way data exchange

- Integrated coupled solutions

Print your part right the first time. Simcenter 3D additive manufacturing capabilities can help you predict distortions and defects before you ever print any parts, thereby reducing the number of test prints and improving the quality of your final print. Specific capabilities in the additive manufacturing solution include:

- Simulate powder-bed fusion build process

- Geometry compensation based on results

Improve and optimize your product designs. Simcenter 3D software optimization solutions relieve the burden of improving product designs by automating the iterative process. This enables you to compare your design’s performance against specifications. It also enables you to start at topology optimization and extend to design space exploration with more classical parametric optimization capabilities. Specific design space exploration and optimization capabilities include:

- Integrated design-space exploration

- Topology optimization

- FE parameter optimization

Trace all of your team’s simulation work and data in a product development context. You can use Simcenter 3D in a seamlessly managed environment integrated with Teamcenter software. When Simcenter 3D is used with Teamcenter integration, you can create, store and access your product simulation data in a Teamcenter database. It combines the power of Simcenter 3D in multiphysics modeling with the power of Teamcenter in storing and retrieving data in a controlled fashion. Capabilities include:

- Integration with Teamcenter simulation

- Rules-based assembly management

Understand how flexible pipes, hoses and cables will react when your part moves. Simcenter 3D includes applications dedicated to helping you simulate the behavior of how flexible pipes, hoses and cables will move and bend within your moving assembly. This application helps you determine and simulate mounting scenarios and calculate initial positions of flexible pipes. Specific capabilities supported include:

- Rubber-like hoses

- Electric cables and wire harnesses

- Mounting scenarios

- Initial and operating positions

- Forces and moments

- Collision and interference checking

- Optimize position and orientation

- Linear and nonlinear dynamics

How ProductSpace Can Help

- Expert Implementation & Configuration

- Training & Enablement

- Ongoing Support & Optimization

Not sure where to start? Our experts are here to help!

Succeeding Together

Our Services & Key Benefits

Technical Support

Ensure smooth operations with expert troubleshooting and system optimization. Our team provides fast, reliable support for PLM and CAD environments, ensuring minimal downtime.

Consultation & Training

Maximize efficiency with expert-led guidance tailored to your business needs. From system implementations to best practices, our consultants help you get the most out of your solutions.

Resource Library

Stay ahead with our collection of webinars, guides, Quick Bytes, and more. Explore expert insights, industry best practices, and practical solutions to optimize your PLM, CAD, and enterprise systems for success.

Accelerate Simulation with Simcenter 3D

Explore how an integrated CAE environment can streamline your modeling, meshing, and simulation workflows.