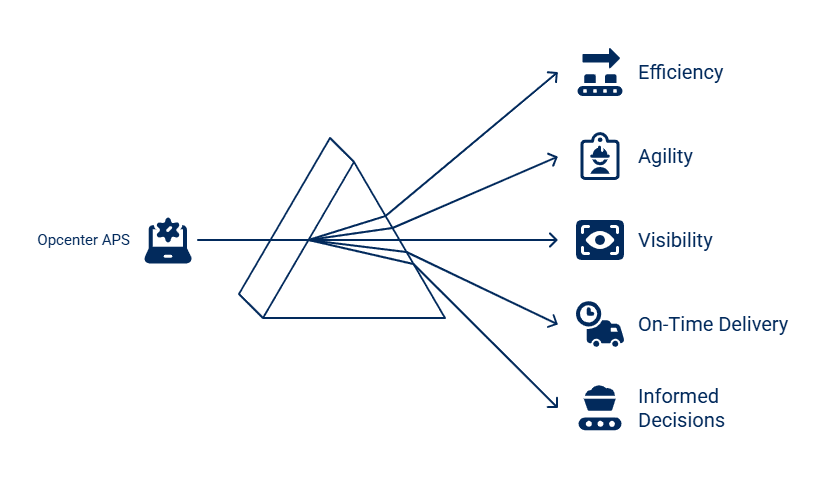

Unveiling Opcenter APS's Manufacturing Solutions

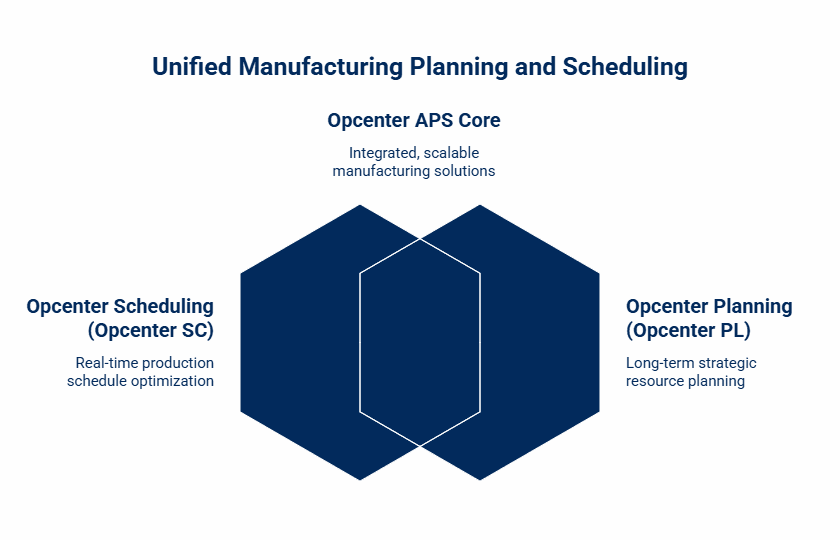

Opcenter APS is not just a single product; it's a comprehensive collection of software offerings, primarily comprising Opcenter Scheduling (Opcenter SC) and Opcenter Planning (Opcenter PL). Whether you're dealing with complex production schedules or long-term strategic planning, Opcenter APS offers tailored solutions, available in various editions from Standard to Ultimate, ensuring you only pay for what you need while allowing for seamless upgrades as your requirements evolve.

Opcenter APS is not just a single product; it's a comprehensive collection of software offerings, primarily comprising Opcenter Scheduling (Opcenter SC) and Opcenter Planning (Opcenter PL). Whether you're dealing with complex production schedules or long-term strategic planning, Opcenter APS offers tailored solutions, available in various editions from Standard to Ultimate, ensuring you only pay for what you need while allowing for seamless upgrades as your requirements evolve.

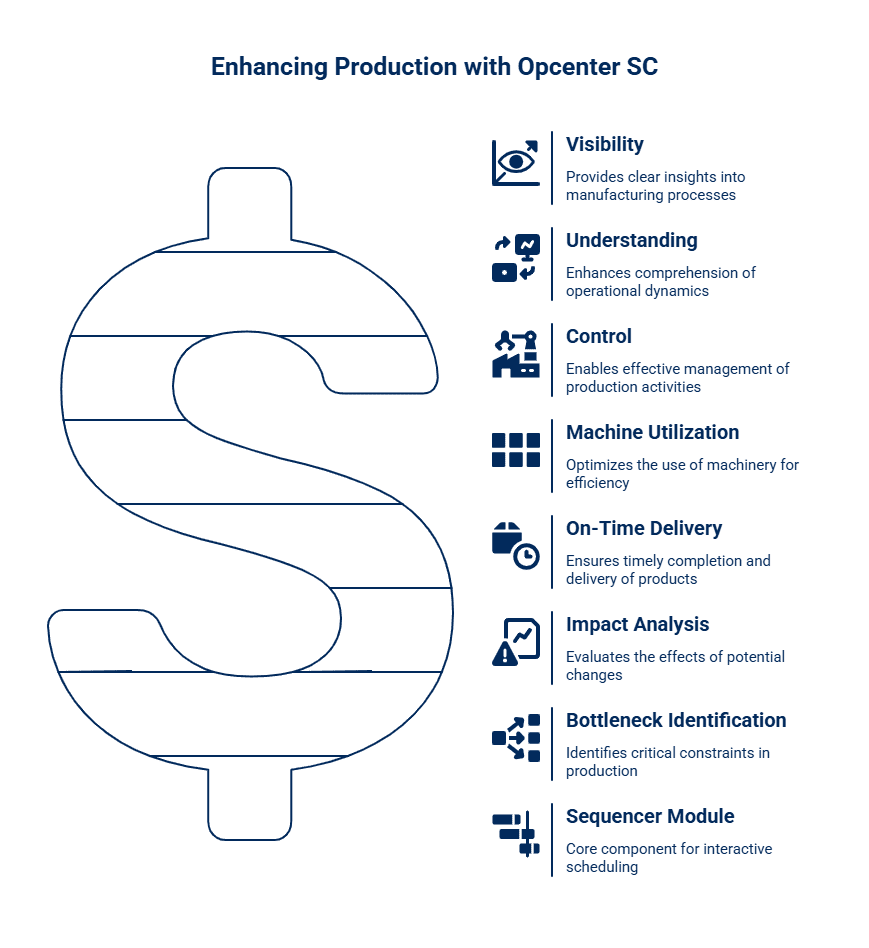

Empowering Your Production with Opcenter SC (Scheduling)

Opcenter SC is your go-to for greater visibility, understanding, and control of manufacturing processes. It empowers you to achieve better machine utilization, enhance on-time delivery, perform impact analysis for 'what-if' scenarios, and identify critical bottlenecks. The Sequencer module is at its core, providing a highly interactive interface for viewing and modifying the sequence of operations, capable of functioning as a simple electronic planning board or a sophisticated multiple-constraint simulation-based scheduling engine.

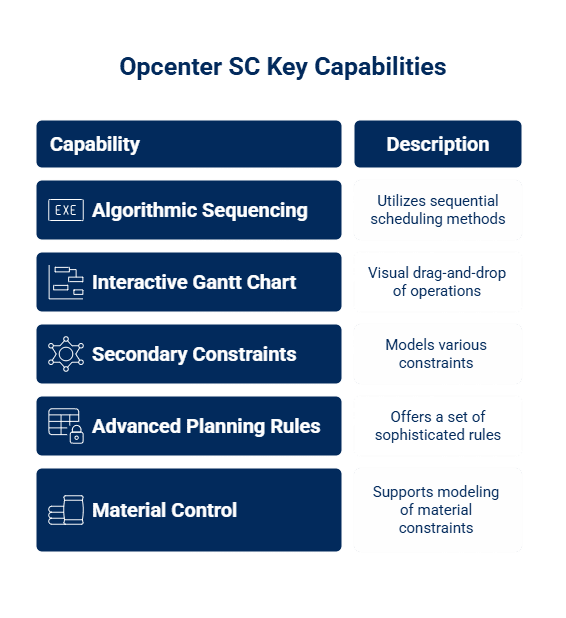

Key capabilities of Opcenter SC include

• Algorithmic Sequencing: Utilizes sequential or 'order at a time' scheduling methods, allowing for rules based on priority, due dates, and more.

• Interactive Gantt Chart: Enables visual drag-and-drop of operations between resources and on-screen updates of completion times.

• Secondary Constraints: Models various constraints like tooling and manning, moving beyond single-constraint scheduling.

• Advanced Planning Rules: Offers a set of sophisticated rules such as APS Forwards, APS Backwards, APS Parallel Loading, and APS Preferred Sequence, with Ultimate editions providing advanced options like Minimize Overall Setup and Minimize WIP.

• Material Control: Supports modeling of material constraints with various pegging rules, allowing for user-defined rules in Professional and Ultimate editions, and linking materials at any operation step. The Material Explorer provides an interactive graphical representation of links between orders, highlighting shortages and unused quantities.

Strategic Long-Term Vision with Opcenter PL (Planning)

For companies navigating volatile, make-to-stock environments, Opcenter PL offers a dependable method for planning capacity and stock. Available exclusively in the Ultimate edition, it is a long-term planning tool crucial for high-level planning decisions based on future demand. The Planner module offers a flexible interface for viewing and modifying production plans based on item-specific parameters and constraints.

Opcenter PL helps you

• Anticipate Demand: Utilizes planning resources, manufacturing preferences, order multiples, minimum order sizes, and shelf life to propose an accurate and achievable Master Production Schedule (MPS).

• Work with Large Data: Unlike spreadsheets, Opcenter APS can handle extensive data volumes.

• Constrained & Unconstrained Production: Supports both finite or infinite capacity planning modes across various time periods (days, weeks, months).

• Interactive 'What-If' Scenarios: Perform calculations with alternative scenarios to realize true cost reductions. You can easily change the MPS by clicking and dragging points on stock or capacity graphs, with changes reflected across all linked plots and grids.

• BOM Explosion: Explodes the planning Bill of Materials (BoM) to calculate production plans for lower-level items and propose material purchase requirements.

Transform Your Operations Today!

Opcenter APS offers a powerful and flexible solution to meet the complex demands of modern manufacturing planning and scheduling. From optimizing daily operations with Opcenter SC to strategic long-term planning with Opcenter PL, its comprehensive features, robust security, and extensive customization options provide the tools you need to achieve operational excellence.