Manufacturing organizations today face unprecedented challenges in maintaining competitive advantage while navigating complex supply chains, evolving customer demands, and the need for rapid innovation. Traditional development approaches often fall short in delivering the agility and responsiveness required in modern manufacturing environments. This is where low-code development platforms like Mendix are revolutionizing how manufacturers approach digital transformation, enabling rapid deployment of mission-critical applications that drive operational excellence.

The Manufacturing Digital Transformation Imperative

The manufacturing industry stands at a critical inflection point. According to recent studies, manufacturers implementing digital transformation initiatives can achieve throughput improvements of 10-30%, reduce costs of quality by 10-20%, and cut machine downtime by up to 50%. Despite these compelling benefits, many manufacturers struggle with the complexity and timeline of traditional software development approaches.

Current Manufacturing Challenges

Modern manufacturers face a complex web of operational challenges that demand innovative technological solutions:

Operational Inefficiencies: Legacy systems and manual processes create bottlenecks that limit productivity and increase operational costs. Traditional manufacturing environments often rely on disconnected systems that prevent real-time visibility and decision-making.

Quality Control Complexity: Ensuring consistent product quality across diverse production lines requires sophisticated monitoring and control systems that can adapt to varying specifications and regulatory requirements.

Supply Chain Visibility: Managing complex supply chains with multiple vendors, varying lead times, and fluctuating demand patterns requires real-time data integration and predictive analytics capabilities.

Workforce Challenges: The manufacturing skills gap continues to widen, requiring organizations to maximize productivity from existing teams while building capabilities for future needs.

How Mendix Empowers Manufacturing Innovation

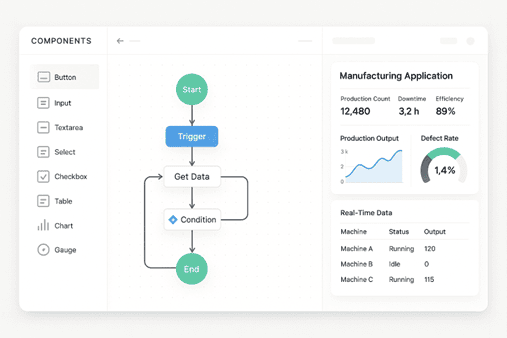

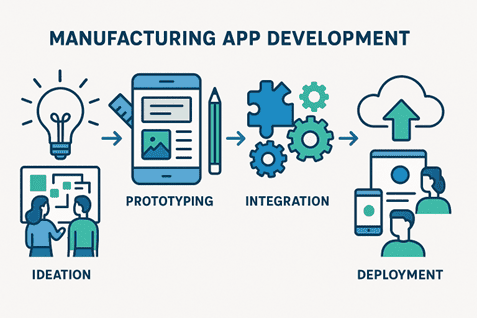

Low-code development platforms are fundamentally changing how manufacturers approach application development and digital transformation. Mendix enables manufacturing organizations to rapidly develop, deploy, and iterate on applications that address specific operational challenges without the lengthy development cycles associated with traditional coding approaches.

Accelerated Development Timelines

Research shows that low-code platforms can reduce development time by up to 90% compared to traditional methods. For manufacturers facing urgent operational challenges or market pressures, this acceleration can mean the difference between maintaining competitiveness and falling behind.

Mendix's visual development environment enables manufacturing teams to prototype and deploy applications in weeks rather than months. This rapid development capability is particularly valuable for addressing seasonal demands, regulatory changes, or unexpected operational challenges that require immediate technological solutions.

Enhanced Integration Capabilities

Manufacturing operations depend heavily on integration between diverse systems including Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), Quality Management Systems (QMS), and Internet of Things (IoT) devices. Mendix's extensive connector ecosystem and API-first architecture enable seamless integration across these complex manufacturing technology stacks.

The platform's ability to connect IT and Operational Technology (OT) systems is particularly valuable in manufacturing environments where shop floor data must be integrated with enterprise systems for comprehensive visibility and control.

Improved User Experience and Adoption

Traditional manufacturing software often suffers from complex interfaces that limit user adoption and productivity. Mendix applications are designed with user experience as a primary consideration, resulting in intuitive interfaces that promote adoption across technical and non-technical users.

Manufacturing organizations report significant improvements in user adoption rates when deploying Mendix applications compared to traditional manufacturing software solutions.

Real-World Manufacturing Applications with Mendix

Leading manufacturers across industries are leveraging Mendix to transform their operations through innovative applications that address specific business challenges:

Quality Management and Inspection Systems

A major automotive manufacturer implemented a Mendix-based quality inspection application that integrates with their existing MES and quality systems. The application provides mobile capabilities for quality inspectors, enabling offline data collection and real-time synchronization when connectivity is available.

Results achieved:

40% reduction in quality inspection time

Improved data accuracy and consistency

Enhanced traceability and compliance reporting

Better visibility into quality metrics across production lines

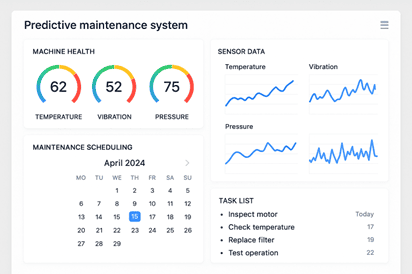

Predictive Maintenance Applications

Siemens has successfully integrated Mendix with their Industrial Edge platform to create predictive maintenance applications that leverage IoT data from manufacturing equipment. These applications analyze machine performance data in real-time to predict potential failures before they occur.

Impact delivered:

30-50% reduction in unplanned downtime

Improved equipment utilization and productivity

Reduced maintenance costs through optimized scheduling

Enhanced worker safety through proactive maintenance

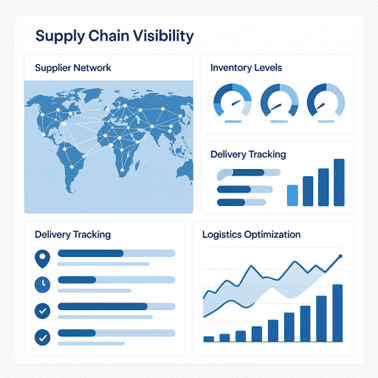

Supply Chain Optimization

A global electronics manufacturer developed a Mendix-based supplier collaboration portal that integrates with their ERP and supply chain management systems. The application provides suppliers with real-time visibility into demand forecasts, inventory levels, and delivery requirements.

Business benefits realized:

25% improvement in supplier response time

Reduced inventory holding costs

Improved on-time delivery performance

Enhanced supplier relationship management

Production Planning and Scheduling

Manufacturing organizations are using Mendix to develop sophisticated production planning applications that optimize resource utilization and minimize lead times. These applications integrate data from multiple sources including demand forecasts, capacity constraints, and material availability to generate optimized production schedules.

Connecting Digital Transformation with Business Results

You can edit text on your website by double clicking on a text box on your website. Alternatively, when you select a text box a settings menu will appear. your website by double clicking on a text box on your website. Alternatively, when you select a text box

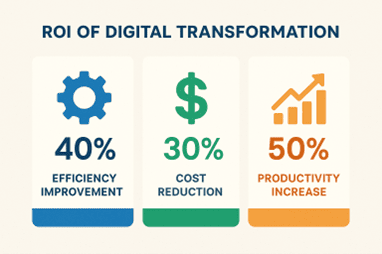

Operational Efficiency Improvements

Manufacturers implementing low-code solutions report significant efficiency gains across key operational metrics:

Overall Equipment Effectiveness (OEE): 15-20% improvement within first year

Cycle Time Reduction: 20-30% decrease in production cycle times

Defect Rate Reduction: 20-25% improvement in first-pass yield

Inventory Optimization: 10-15% improvement in inventory turnover

Cost Reduction Benefits

Digital transformation initiatives using low-code platforms deliver substantial cost savings:

Development Costs: Up to 70% reduction compared to traditional development

Operational Costs: 10-20% reduction through process optimization

Maintenance Costs: 30-40% decrease through predictive maintenance

Quality Costs: Significant reduction in rework and warranty claims

Strategic Business Value

Beyond operational improvements, Mendix implementations provide strategic value that enhances long-term competitiveness:

Enhanced Agility: Rapid response to market changes and customer requirements

Innovation Acceleration: Faster time-to-market for new products and services

Competitive Advantage: Improved operational efficiency and customer satisfaction

Risk Mitigation: Better compliance and quality control capabilities

Why ProductSpace is Your Ideal Digital Transformation Partner

For manufacturing organizations seeking to leverage low-code platforms like Mendix for their digital transformation initiatives, partnering with experienced technology consultants provides crucial advantages. ProductSpace brings unique value to manufacturing digital transformation projects through their comprehensive approach to technology implementation and business transformation.

Deep Manufacturing Domain Knowledge: ProductSpace understands the complexities of manufacturing operations, from supply chain management to quality control systems. Their team has extensive experience working with manufacturers across diverse industries, enabling them to quickly understand unique operational requirements and challenges.

Cloud-Native Expertise: With specialized capabilities in cloud infrastructure and AWS hosting services, ProductSpace ensures that Mendix applications are deployed in scalable, secure, and high-performance environments. Their cloud expertise is particularly valuable for manufacturing organizations seeking to modernize their IT infrastructure while implementing new applications.

Comprehensive Implementation Support: ProductSpace provides end-to-end support for digital transformation initiatives, from initial strategy development through implementation, training, and ongoing support. This comprehensive approach ensures successful adoption and maximum return on investment.

Industry Best Practices: Drawing from extensive experience across manufacturing environments, ProductSpace brings proven methodologies and best practices that accelerate implementation timelines and improve project outcomes.

Scalability and Growth Support: As manufacturing organizations expand their digital transformation initiatives, ProductSpace provides the expertise and resources needed to scale applications and capabilities across multiple facilities and business units.

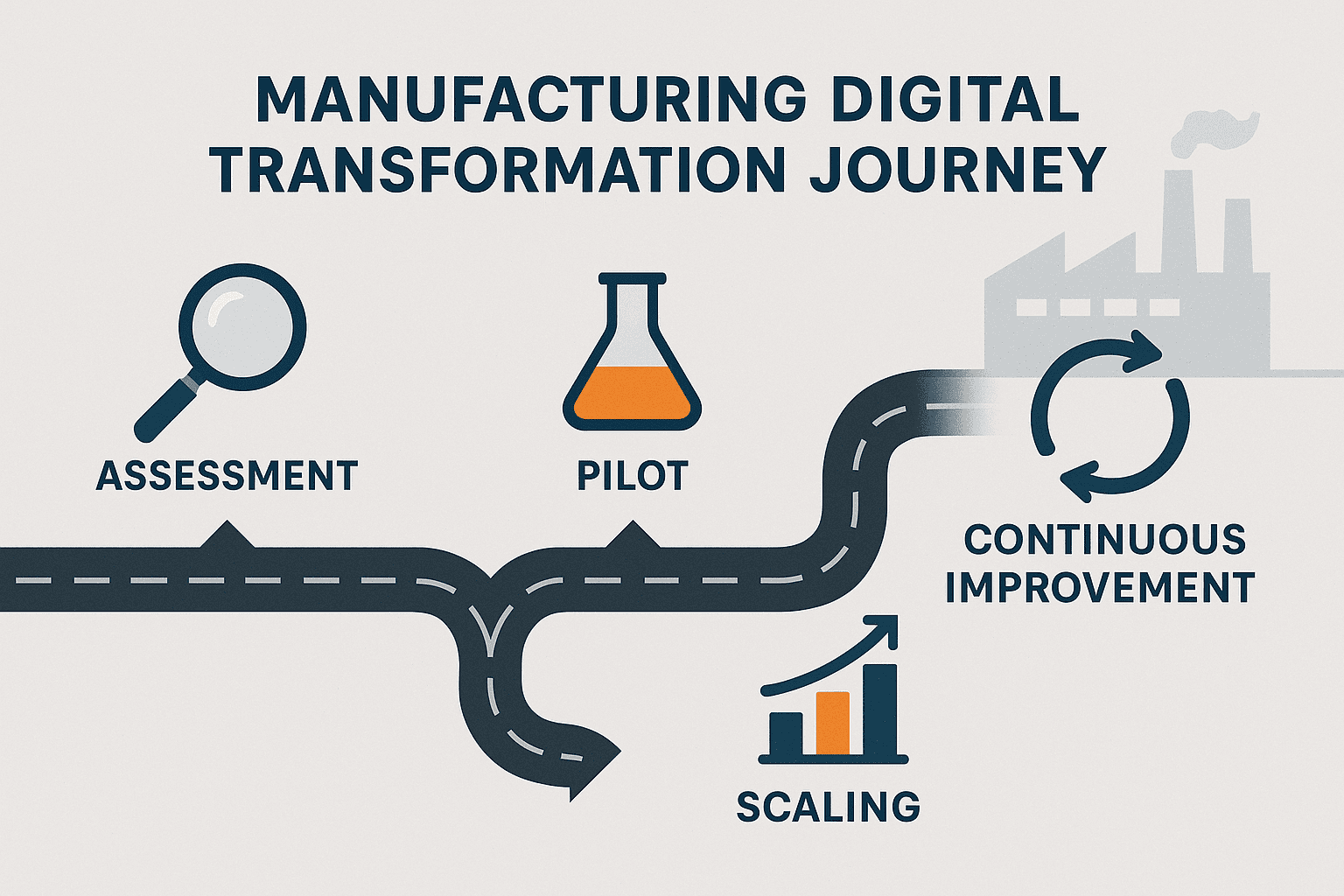

Building Your Manufacturing Digital Transformation Strategy

Successful manufacturing digital transformation requires a strategic approach that aligns technology investments with business objectives and operational requirements:

1. Assess Current State and Define Objectives

Conduct comprehensive assessments of existing systems, processes, and capabilities to identify digital transformation opportunities. Establish clear, measurable objectives that align with business strategy and operational priorities.

2. Prioritize High-Impact Use Cases

Focus initial efforts on applications that deliver maximum business value and demonstrate the potential of low-code development. Successful pilot projects build organizational confidence and momentum for broader transformation initiatives.

3. Design for Integration and Scalability

Develop application architectures that integrate seamlessly with existing systems while providing the flexibility to scale across the organization. Consider data integration requirements, security needs, and performance criteria from the project outset.

4. Build Internal Capabilities

Invest in training and capability development to enable internal teams to contribute to application development and maintenance. Low-code platforms enable broader participation in development activities, reducing dependence on specialized technical resources.

5. Establish Governance and Standards

Implement governance frameworks that ensure consistent application development practices, data management, and security standards across the organization.

Measuring Success: ROI Metrics for Manufacturing Digital Transformation

Successful digital transformation initiatives require clear metrics that demonstrate business value and guide ongoing optimization efforts:

Financial Metrics

Development ROI: Track cost savings and efficiency gains from accelerated development cycles

Operational Savings: Measure cost reductions from improved processes and resource utilization

Revenue Impact: Assess revenue gains from improved customer service and operational capabilities

Operational Performance Indicators

Equipment Utilization: Monitor improvements in Overall Equipment Effectiveness (OEE)

Quality Metrics: Track defect rates, first-pass yield, and customer satisfaction scores

Productivity Measures: Assess throughput improvements and cycle time reductions

Strategic Value Indicators

Time-to-Market: Measure improvements in new product development and launch timelines

Innovation Velocity: Track the pace of new application development and deployment

Competitive Position: Assess market position and customer satisfaction improvements

The Future of Manufacturing with Low-Code Development

As manufacturing continues to evolve, low-code development platforms will play an increasingly important role in enabling rapid innovation and adaptation to changing market conditions:

AI-Enhanced Manufacturing: Integration of artificial intelligence and machine learning capabilities into manufacturing applications will provide predictive insights and automated decision-making capabilities.

Edge Computing Integration: Low-code platforms will increasingly support edge computing deployments that enable real-time processing and analysis of manufacturing data at the point of collection.

Sustainable Manufacturing: Applications that support environmental sustainability initiatives will become increasingly important as manufacturers focus on reducing environmental impact and meeting regulatory requirements.

Advanced Analytics: Integration of advanced analytics and visualization capabilities will provide deeper insights into manufacturing performance and optimization opportunities.

Getting Started with Mendix for Manufacturing

For manufacturing organizations ready to begin their low-code digital transformation journey, Mendix provides a comprehensive platform that addresses the unique requirements of manufacturing environments:

Manufacturing-Specific Templates: Mendix offers pre-built templates for common manufacturing use cases, accelerating initial development and providing proven starting points for custom applications

Industry Expertise: The Mendix team includes manufacturing domain experts who understand industry-specific requirements and challenges.

Scalable Platform: The platform supports deployment across multiple manufacturing facilities and can scale to support enterprise-wide digital transformation initiatives.

Integration Capabilities: Extensive connector ecosystem enables integration with common manufacturing systems including ERP, MES, QMS, and IoT platforms.

Next Steps for Your Digital Transformation Journey

Manufacturing organizations seeking to accelerate their digital transformation initiatives through low-code development should consider these strategic steps:

Evaluate Current Challenges: Assess existing operational challenges and identify high-impact use cases for digital transformation

Develop Pilot Strategy: Design focused pilot projects that demonstrate value and build organizational capability

Engage Expert Partners: Work with experienced consultants who understand both manufacturing operations and low-code development

Plan for Scale: Develop architectures and governance frameworks that support organization-wide transformation

Conclusion

The convergence of low-code development and manufacturing digital transformation represents a significant opportunity for organizations seeking to enhance operational efficiency, improve quality, and accelerate innovation. Mendix provides the tools and capabilities needed to rapidly develop and deploy manufacturing applications that deliver measurable business results.

Success in manufacturing digital transformation requires more than just technology implementation—it demands strategic thinking, domain expertise, and comprehensive support throughout the transformation journey. Organizations that combine the power of low-code platforms with expert guidance and proven methodologies will be best positioned to achieve their digital transformation objectives.

Ready to accelerate your manufacturing digital transformation journey? ProductSpace combines deep technology expertise with comprehensive understanding of manufacturing operations to deliver successful digital transformation outcomes. Our team of experts can help you develop and implement a strategic approach to low-code development that aligns with your operational requirements and business objectives.