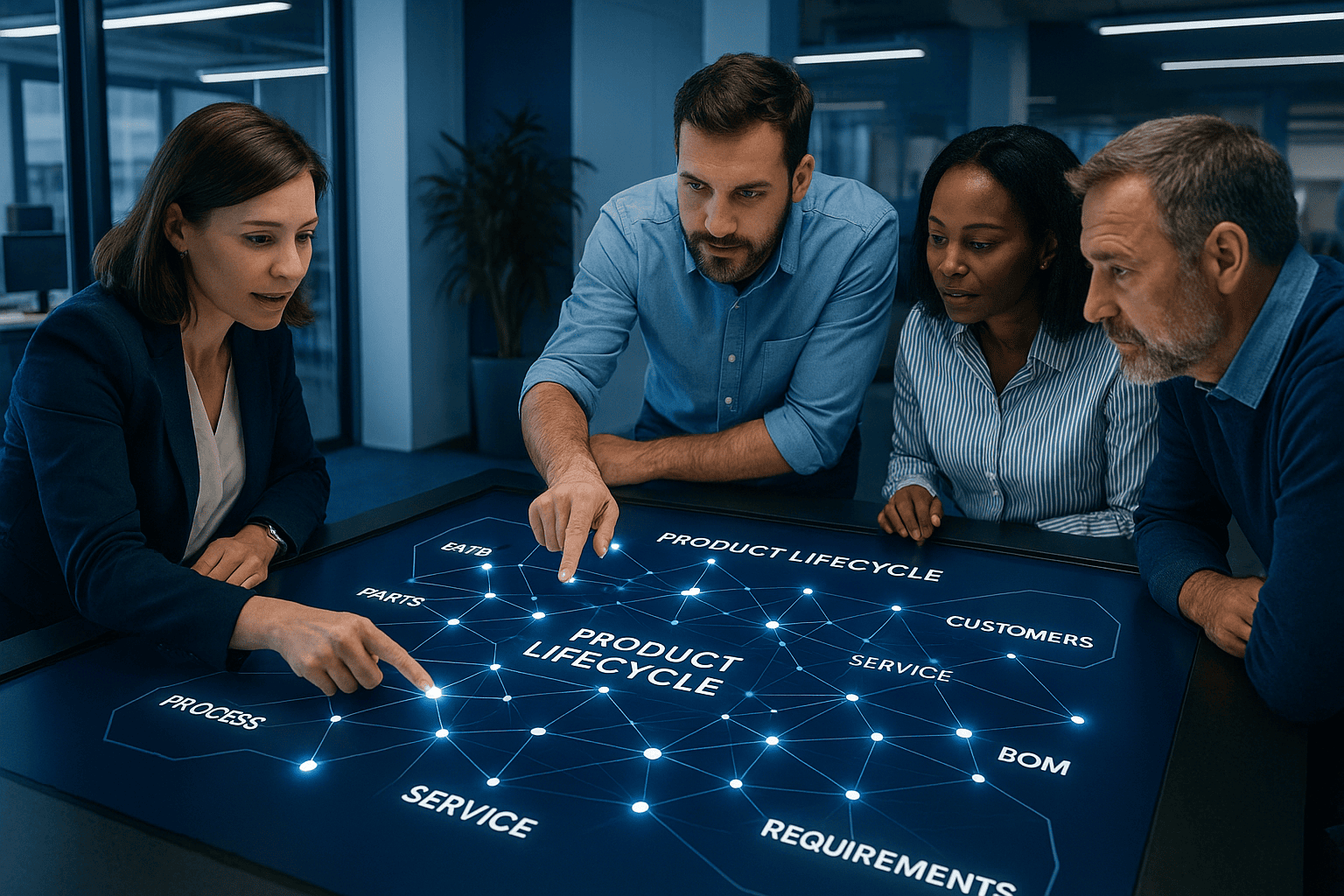

Why PLM Is the Nervous System of Modern Product Development

Product Lifecycle Management (PLM) has evolved from an engineering vault to the central nervous system connecting design, manufacturing, service, and the customer. In 2025, AI powered automation, cloud delivery, and the push for sustainable product development have made PLM indispensable for companies of every size. This guide demystifies PLM, what it is, why it matters, and how to implement it, so you can turn ideas into profitable, compliant products faster.

What is PLM?

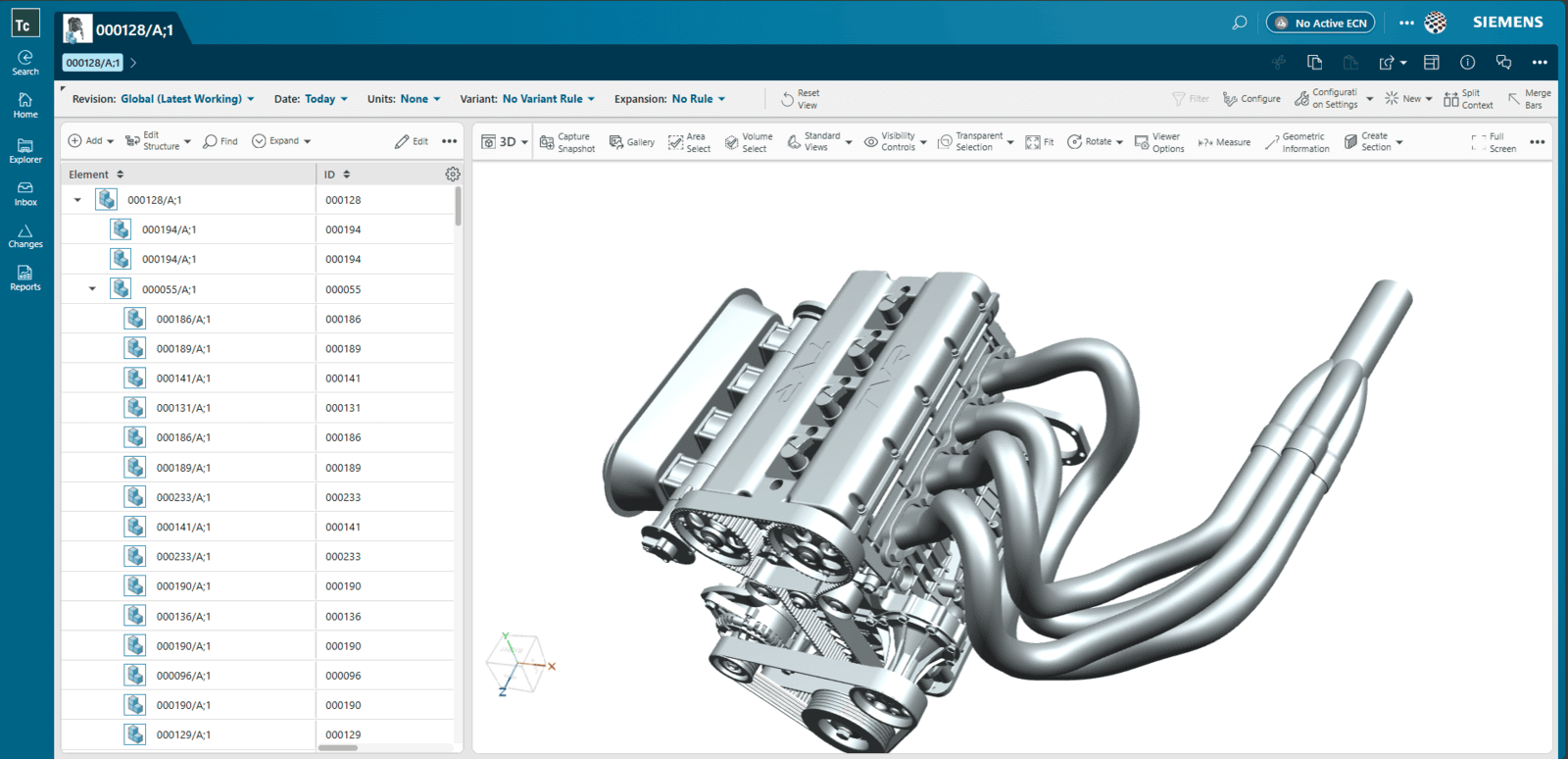

PLM is an enterprise strategy and software environment that manages product data, processes, and stakeholders from concept through service. Solutions like Siemens Teamcenter create a single source of truth for CAD files, bills of materials (BOMs), requirements, and changes, bridging silos across engineering, manufacturing, and supply chain.

Why PLM Matters in 2025

Timetomarket pressure: Customization and compressed lead times demand instant access to accurate data.

Compliance & traceability: Regulations such as EU Digital Product Passport require digital records from cradle to grave.

Sustainability goals: Lifecycle assessment (LCA) tools embedded in PLM help quantify carbon impact.

AI & automation: Generative design and predictive maintenance feed on clean, structured lifecycle data.

Core Components of a Modern PLM Stack

Layer | Key Capabilities |

Foundation | Secure data vault, revision control, rolebased access |

Collaboration | MultiCAD management, BOM visualization |

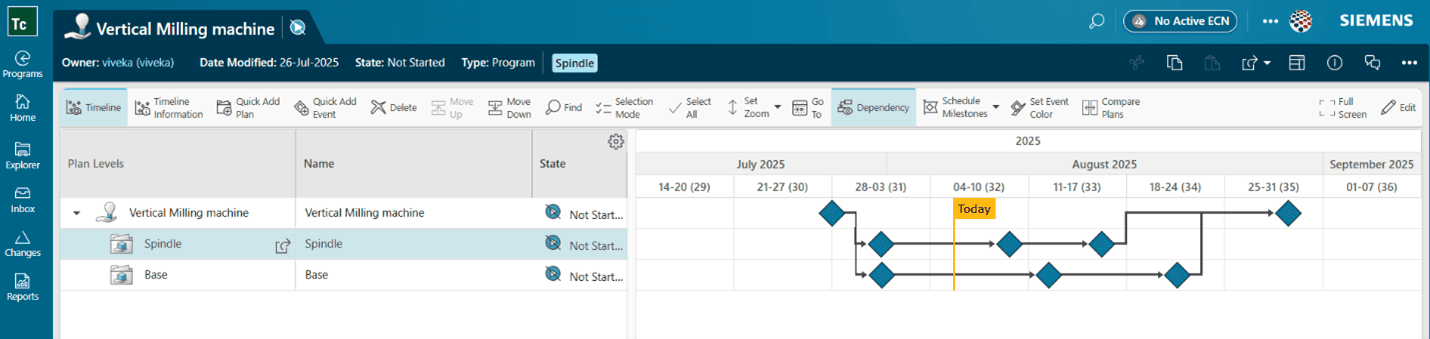

Process | Change management, workflows, requirements traceability |

Integration | ERP/MES connectors, API/Microservices |

Insights | Analytics, dashboards, AI recommendations |

Implementing PLM: Roadmap & Best Practices

Define success metrics (e.g., ECO cycle time, firstpass yield).

Establish governance, exec sponsor, core team, steering committee.

Start with a digital thread pilot: CAD → BOM → Change.

Iterate and scale: Add requirements, manufacturing process planning, service.

Timeline tip: Midmarket firms typically reach Phase 1 go-live in 46 months with a preconfigured template such as Teamcenter Rapid Start.

Case Studies & ROI Benchmarks

ZF – Cost & Emissions Optimization with Teamcenter PCM

American Axle – Achieving Target Costs with Product Costing

American Axle & Manufacturing (AAM) leverages Teamcenter Product Costing to manage complex cost scenarios, conduct transparent supplier workshops, and make fact-based decisions early in development. By unifying cost data and applying both bottom-up and top-down methods, they continuously reduce product costs and improve profitability. Discover how AAM is using Teamcenter to optimize cost management across its global supply chain.

JCB – Driving Digital Twin Success and Reuse at Scale

Faced with over 200,000 machine variations, JCB turned to Siemens solutions like Teamcenter, NX, and Geolus to improve efficiency, speed up design reuse, and ensure consistency across global teams. With shape search and digital BOM configuration, they reduced part duplication, improved accuracy, and built a scalable platform for innovation. Explore how JCB uses PLM to deliver smarter, faster product updates across a highly configurable product line.

Teamcenter X – Total Economic Impact (TEI) Report by Forrester

According to Forrester, Teamcenter X delivers a potential 241% ROI in just three years—thanks to faster change management, lower IT overhead, and streamlined collaboration. The report highlights real customer outcomes, including significant reductions in unplanned downtime and time-to-value. Read the full report to see how Teamcenter X delivers measurable business impact across engineering organizations.

Future Trends: AI, Cloud, and the Digital Twin

AI copilots generate part variants, while cloudnative offerings like Teamcenter X deliver instant scalability and lower IT overhead. Coupled with IIoT data, the digital twin closes the feedback loop between asdesigned, asbuilt, and asoperated states.

How ProductSpace Helps

Implementation & migration: Proven RapidStart playbooks.

pSIM for integration: Seamless PLMtoERP/MES data exchange, no middleware headaches.

Windchill360 & Teamcenter360 cloud hosting: Secure, compliant, managed services.

RAPiDS: Remote PLM administration that scales with you.

Conclusion & Next Steps

Ready to transform disconnected data into a competitive asset? Book a 30-minute PLM discovery call and see how quickly you can create your digital thread.